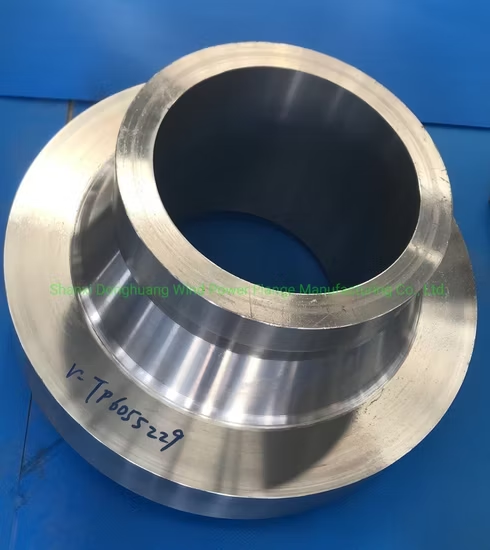

Oil Petroleum Machine Wireline Downhole Drilling Tools API Injector Perforating Gun with Sliding Sleeve Drilling Tools

Description

Basic Info

| Warranty | Unavailable |

| Manufacturing Process | CNC Milling |

| Surface Treatment | Without Processing |

| Operation Pressure | Atmospheric Pressure |

| Material | Stainless Steel |

| Certification | API |

| Use | Oil Well |

| Transport Package | Wooden Case |

| Specification | According to the custom |

| Trademark | Tolian |

| Origin | China |

| HS Code | 8431431000 |

| Production Capacity | 1000piece/Month |

Product Description

Perforating Gun with Sliding Sleeve1.Application1) Hydraulic sand jetting & fracturing is well stimulation which combined of perforating, fracturing and isolation, it's an important technology to keep oilfield stable production.2) Apply to low-permeability reservoir, thin reservoir and edge-bottom water reservoir;3) Suitable for casing, screen pipe and barefoot well completion vertical well, horizontal well's multistage perforating fracturing operation. 2.Working PrincipleHydraulic Jetting & Fracturing technology--- jet-flow formed a boost pressure in the channels. Pumping the fluid increased the annulus pressure, the superimposing of both the pressure over the fracturing pressure and then man-made the stratum.Hydraulic isolating technique---By control the jetting tool to chose the position and orientation of the crack initiation accurately; After the crack formed, the high-speed fluid jetting into the pore passage and the crack,the pore passage same as the "Jetting pump"; The annulus fluid under the function of the pressure difference was intaked stratum,maintain the extension of the cracks and realize the hydraulic isolation.3.OperationThe Perforating Gun with Sliding Sleeve has a self-sealing effect and can realize multi-stage perforating and fracturing operation only by running the string downhole once.During the perforating and fracturing, a steel ball will be dropped into the first sliding sleeve, by pressuring to the tubing and cut off the pin to make the sliding sleeve down to the sliding sleeve seat to setting, blocking the tubing, abrasive perforating; Pumping fracturing fluid into the tubing to maintain the pressure drop of the nozzle, applied pressure by annulus, fracture; After finish fracturing, shut in for a period of time,drop ball to the second sliding sleeve, setting, perforating and fracturing repeatedly.

Casing Type | Max.OD of Perforating Gun | Working Pressure | QTY of Nozzle | Size of Nozzle | Type of Nozzle | Operation |

4 1/2" | 90mm | 10000Psi |

2~8 | 3.5mm~ 6.7mm | 2 3/8" UP TBG | Tubing/ Coiled Tubing |

5 1/2" | 105mm | 2 7/8" UP TBG |

Prev: Eccentric Water Injection Tool From China

Next: Oil Well Tools Coiled Tubing, Seamless Stainless Steel Coiled Tubing

Our Contact